Do you need a machine that will form both FLAT and ROUND copper wire?

Do you need a machine that can easily make copper wire prototypes?

Do you need xEV parts production capabilities?

Asahi-Seiki machines are the solution.

Sample Parts

Hairpin coil

A part used in the hairpin method and utilized for the drive motor.

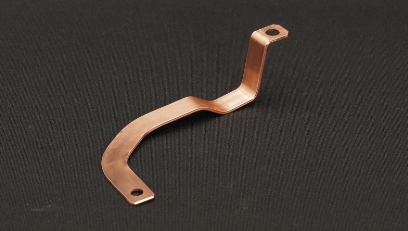

Bus bar

A part used to connect the power supply to each component.

Piercing

Piercing capabilities.

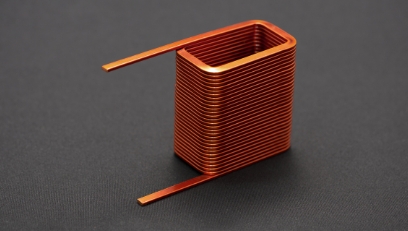

Edgewise coil

Used for in-vehicle DC-DC converters.

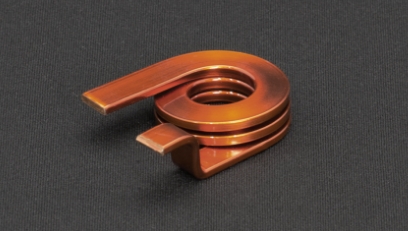

Choke coil

Used to eliminate noise.

New features for xEV parts

The belt-feed feature ensures precise distribution of pressure to

copper material, thus preventing wire deformation.

Additional benefits

Universal forming unit (USF-PC) / Universal slide (T2)

The forming tool can be positioned as close as possible to minimize any negative material tendencies.

Creating a radius with the coil forming tool is also possible.